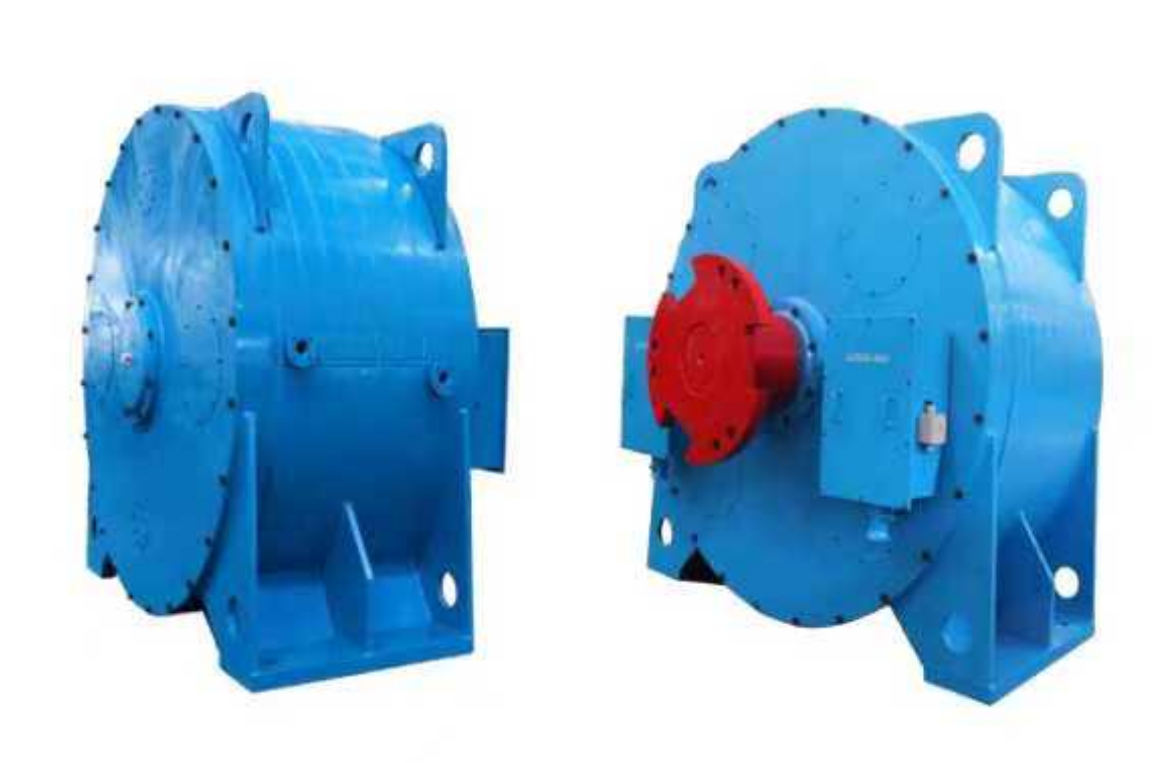

The permanent magnet motor mine hoist adopts an external rotor permanent magnet synchronous motor, the permanent magnet is installed on the inner wall of the drum as the external rotor of the permanent magnet motor, and the working winding coil is fixed on the main shaft as the motor stator. The technical features of the permanent magnet synchronous motor are multi-series, low frequency, low speed, high torque, and low frequency converter is used for speed regulation. Compared with the traditional hoist, the permanent magnet built-in mine hoist has broken through a number of key technologies, and the product technology is the international leader, which has the incomparable advantages of the traditional hoist.

Comparison Table of Advantages between Permanent Magnet Motor Mine Hoist and Traditional Hoist

Well depth 500m, speed 3 m/s, load 135KN, voltage 660V, four-quadrant inverter

| Contrast content | Permanent magnet motor mine hoist model JKN-3 * 2.2P | Traditional mine hoist model JK-3 * 2.2P | |

| Motor power | 405KW | 450KW | Power decreased by 10% |

| Full load current | 376A | 559A | Current decreased by 33% |

| Overall efficiency | 95% | 77% | Increased efficiency by 23% |

| power factor | 0.99 | 0.8 | 24% increase in power factor |

| energy saving effect | Complete a lifting (full load) and lowering (no load) process power consumption of 16.3 degrees | Complete a lifting (full load) and lowering (no load) process power consumption of 22.3 degrees | Energy saving 37% |

| Noise | 65 decibels | About 85 decibels | Realize quiet and low noise in computer room |

| Whole machine weight | 47 tons | 55 tons | Weight minus 15% |

| Host floor area | 56 square meters | 80 square meters | Reduction of foundation construction volume by 30% |

| Host installation | Host installation takes only 3 days | Need technical guidance, installation cycle 7-10 days | Significantly shorten the construction period, save materials and labor |

| mainframe maintenance | Host maintenance-free | Regularly check the reducer and coupling, replace the gear oil, and consume materials and manpower. | Save a lot of consumables and labor |

| Security | Even if the brake fails, it can also achieve slow descent to prevent stall "flying" | Failure of safety brakes causes stall "flying" | Increased security level |

| speed control accuracy | 0.00.-3m/s | 0.3-3m/s | Speed control accuracy increased by 100 times |

Key Words

Permanent magnet motor mine hoist

Contact Us

Classification